Table of Contents

In Bitcoin mining, profitability is rarely destroyed by dramatic failures. It is slowly eroded by small operational decisions that compound over time. Among these, few are as consistently underestimated as delayed repairs in mining operations.

Most miners think about downtime in terms of machines being offline. What they often fail to account for is the structural cost created when repairs are not handled with speed, discipline, and system-wide coordination. Delayed repairs do not simply reduce hashrate. They reshape cash flow, increase operational risk, and quietly sabotage long-term returns.

This is not a hardware problem. It is an execution problem.

And in industrial mining, execution is everything.

For mining fundamentals and global industry context:

https://bitcoin.org/en/bitcoin-paper

Why Delayed Repairs Are More Dangerous Than They Appear

When an ASIC goes offline, the visible cost is simple: lost hashrate for a certain period. But the invisible cost is far larger.

Delayed repairs in mining operations create a chain reaction:

• Lost daily revenue

• Increased variance in payout

• Lower fleet efficiency

• Higher failure correlation

• Disrupted load management

• Compromised power planning

• Misleading performance data

Each delay compounds across hundreds or thousands of units. What looks like a “small backlog” in a repair queue becomes a structural revenue leak when scaled.

In professional mining environments, uptime is not just about machines running. It is about how fast failures are detected, isolated, diagnosed, and resolved.

The True Cost Is Not Downtime. It Is Lost Opportunity

A miner that sits idle is not just losing revenue. It is losing time-sensitive opportunity.

Mining is a competitive, difficulty-adjusted business. Every block mined by someone else during your downtime permanently shifts revenue away from you.

Delayed repairs in mining operations mean you are not simply “missing out” on income. You are permanently surrendering your share of a finite issuance schedule.

There is no catch-up later.

The network does not wait for your maintenance.

Why Repairs Get Delayed in Most Mining Operations

Delayed repairs rarely happen because operators do not care. They happen because systems are poorly designed.

The most common causes are:

1. Repair Queues With No Prioritization

Not all failures carry the same economic weight. A hashing board failure on a high-efficiency unit during peak difficulty is far more costly than a minor fan issue on an older model.

Yet many operations treat repairs on a first-come basis rather than by revenue impact.

This leads to:

– Capital misallocation

– Slower revenue recovery

– Misuse of technician time

Professional mining operations prioritize by economic impact, not chronological order.

2. Spare Parts Bottlenecks

Delayed repairs in mining operations are often not caused by lack of labor but by lack of parts.

If spare PSUs, control boards, or hashboards are not locally stocked, every failure becomes a logistics problem rather than a technical one.

This creates:

– Extended offline windows

– Shipping delays

– Customs friction

– Repair batching instead of continuous flow

At scale, this turns maintenance into a supply chain problem, not an engineering problem.

3. Poor Failure Detection Systems

Many failures are not immediately obvious.

Silent failures, partial hashing, unstable boards, or firmware-induced throttling can leave machines technically “online” but economically impaired.

Without real-time monitoring, delayed repairs become invisible until profitability has already suffered.

This is why modern operations rely on:

– Continuous telemetry

– Hashrate deviation alerts

– Thermal anomaly detection

– Auto-isolation protocols

Delayed repairs in mining operations often begin long before anyone realizes a unit is underperforming.

How Delayed Repairs Distort Performance Metrics

One of the most dangerous side effects of delayed repairs is data pollution.

When broken or underperforming machines remain mixed with healthy ones:

• Fleet efficiency metrics become unreliable

• ROI calculations are skewed

• Hosting performance looks worse than it is

• Power utilization appears inefficient

• Cooling systems seem underperforming

The operation starts optimizing around false data.

At that point, the problem is no longer just delayed repairs. It becomes misdirected strategy.

The Financial Compounding Effect

The real damage from delayed repairs in mining operations is compounding.

Let’s break it down:

A single unit offline for 10 days is bad.

100 units offline for 10 days is catastrophic.

But the deeper damage comes when:

– Repairs backlog overlaps

– Failures cluster seasonally

– Difficulty rises during downtime

– Energy contracts remain fixed

– Cash flow becomes unstable

Now the business is no longer losing revenue. It is losing financial predictability.

And financial predictability is what separates industrial mining from speculation.

Why Institutional Miners Obsess Over Repair Velocity

Retail miners ask: “How many machines are running?”

Institutions ask: “How fast can we restore full capacity after failure?”

This is a critical difference.

Professional mining operations measure:

• Mean time to detect failure (MTTD)

• Mean time to repair (MTTR)

• Mean time between failures (MTBF)

• Repair throughput per technician

• Failure clustering patterns

Delayed repairs in mining operations are not acceptable at institutional scale because every hour compounds against capital deployed.

How Delayed Repairs Increase Revenue Risk, Not Just Downtime Risk

Downtime risk is obvious. Revenue risk is structural.

Delayed repairs introduce revenue risk by:

– Increasing payout variance

– Reducing predictability

– Amplifying exposure to difficulty changes

– Disrupting hedging strategies

– Weakening liquidity planning

This is why serious miners do not view repairs as a technical department.

They treat repairs as a financial control layer.

Why Bitmern Mining Treats Repairs as Infrastructure, Not Service

At Bitmern Mining, maintenance and repair workflows are designed as part of the infrastructure itself, not as afterthoughts.

This means:

• Local spare part availability

• Repair prioritization by revenue impact

• Integrated monitoring systems

• Structured escalation paths

• Repair velocity as a KPI

• Continuous optimization of MTTR

Because delayed repairs in mining operations are not just technical issues. They are financial inefficiencies.

And financial inefficiencies scale faster than hardware.

For professional hosting and infrastructure solutions: https://bitmernmining.com/

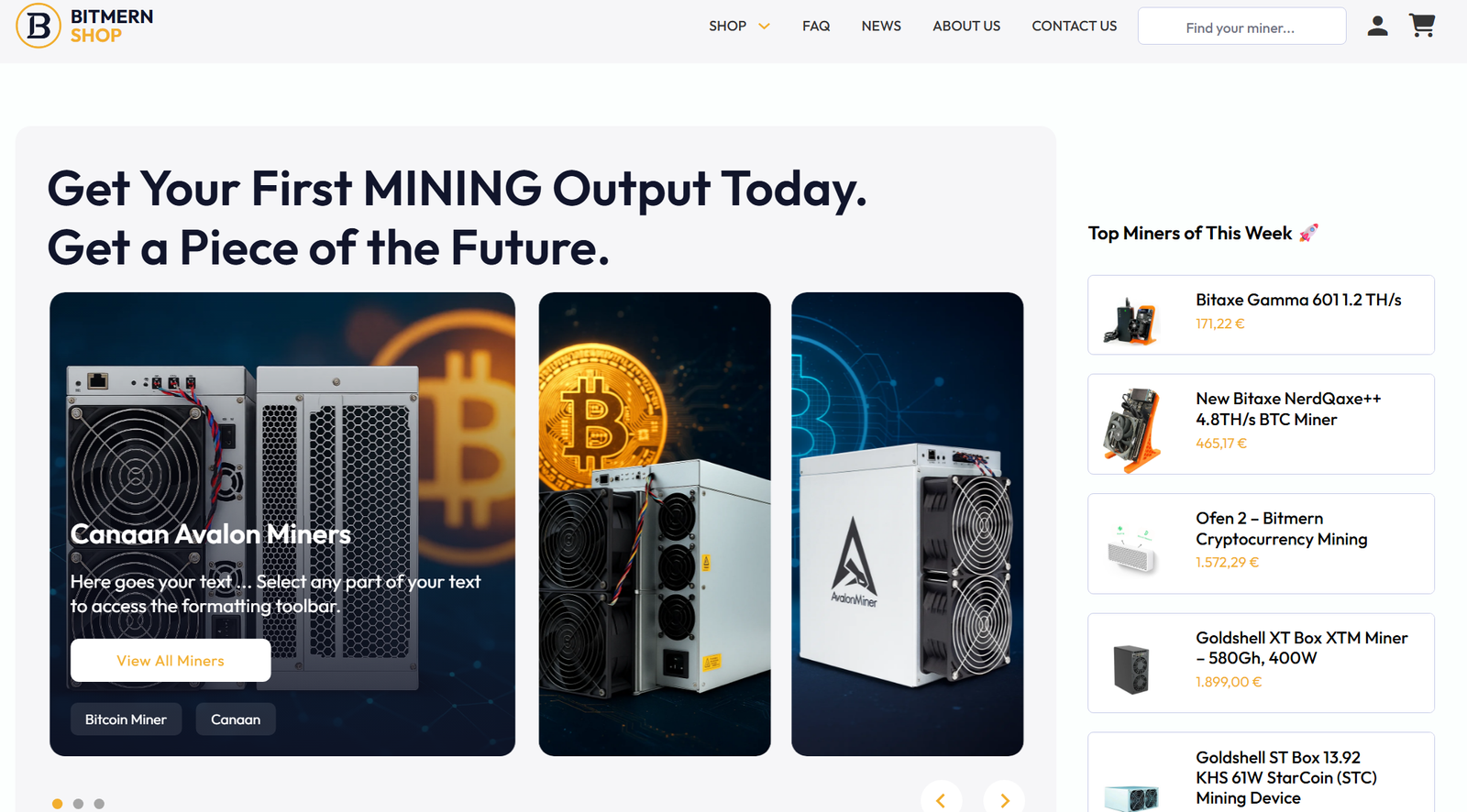

How the Bitmern Shop Reduces Repair Delays Before They Even Exist

Many repair delays originate not at the site, but at the moment of hardware acquisition.

Gray market units, poorly refurbished miners, or mismatched firmware profiles dramatically increase failure rates and complicate maintenance.

The Bitmern Shop focuses on:

– Verified hardware

– Known repair history

– Proper binning

– Compatible firmware profiles

– Predictable failure behavior

This reduces:

• Unexpected failures

• Incompatible spare needs

• Repair complexity

• Diagnostic time

You are not just buying miners. You are buying repair predictability.

Explore verified miners here: https://shop.bitmernmining.com/

Delayed Repairs and the Myth of “Just Add More Hashrate”

Some miners believe they can “outscale” operational inefficiencies by simply adding more machines.

This is false.

Delayed repairs in mining operations scale faster than hashrate.

Because:

– More machines mean more failure points

– More failures increase repair backlog

– Backlog increases downtime variance

– Variance destroys capital efficiency

At scale, operational discipline beats raw hashrate every time.

Why Fast Repairs Are a Competitive Advantage

In markets with thin margins, competitive advantage rarely comes from buying the cheapest machine.

It comes from:

– Faster deployment

– Higher uptime

– Lower variance

– Faster recovery

– Cleaner data

– Better capital control

Mining is not won by who buys hardware fastest.

It is won by who keeps it productive longest with minimal friction.

Final Perspective: Delayed Repairs Are Invisible Until It Is Too Late

The most dangerous operational problems in mining are not dramatic failures. They are silent inefficiencies.

Delayed repairs in mining operations rarely make headlines.

They simply erode margins, distort performance, and quietly destroy capital efficiency.

In a business where every block is contested globally, slow execution is not neutral.

It is a structural disadvantage.

The miners who survive cycles are not the ones who chase peak hashrate.

They are the ones who control operational decay.

And operational decay almost always begins with delayed repairs.